You'll find jewelers brass to be an incredibly versatile metal for your creative work, with its blend of 85% copper and 15% zinc offering both durability and beauty. At a melting point of 1,710°F, it's perfect for casting and cold-working techniques like rolling and shaping. While prices have risen to $4.50 per pound, you can still create stunning filigree work and sculptural forms that capture light beautifully. The deeper you explore this alloy's potential, the more its secrets unfold.

Physical and Chemical Composition

Brass, that alluring golden metal that's made my palms sweat more times than I'd care to admit, isn't just a simple material.

You'll find it's primarily a blend of copper and zinc, with jewelers brass typically containing about 85% copper and 15% zinc. When you're holding it, you can feel its relatively low melting point of 1,710°F (932°C) affecting its workability – trust me, I've learned this the hard way.

You're looking at a metal that's surprisingly dense at 8.4-8.7 g/cm³, and if you've ever tried to scratch it, you'll notice its Mohs hardness of 3 to 4.

Pick up a piece of brass and you'll feel its surprising heft, while your fingernail can leave a mark on its surface.

The chemical composition gives it that warm, yellow hue you'll recognize instantly, though it'll develop a darker patina if you don't handle it carefully.

Manufacturing Techniques and Processes

Crafting jewelers brass demands a delicate dance between precision and patience – I've learned this through countless hours at my workbench, where every mistake feels like it's etched into my memory.

You'll start with the basic cold-working techniques: rolling, drawing, and shaping the alloy until your fingers know the metal's resistance by heart.

When you're ready for casting, you'll heat your brass to that heart-stopping 1,652°F sweet spot where it transforms into liquid gold.

Here's where you'll hold your breath – one degree too hot and you'll volatilize the zinc, too cold and you'll get a grainy mess.

Through forging and annealing cycles, you'll need to maintain strict temperature control while working quickly.

Trust me, you'll never forget the acrid smell of overheated brass or the sinking feeling when a casting goes wrong.

Environmental Impact and Sustainability

While recycling brass might seem straightforward, I've witnessed firsthand how the environmental impact of jewelry making keeps me up at night.

You'll notice the toxic fumes from metal refinement processes wafting through workshops, leaving that distinct metallic taste on your tongue. It's not just about the material waste – you're dealing with heavy metal contamination that'll seep into groundwater if you're not careful.

You can't ignore how the mining of zinc and copper, brass's primary components, devastates landscapes.

But there's hope: you'll find that implementing closed-loop recycling systems and using eco-friendly cleaning solutions makes a difference.

When you're choosing your materials, opt for certified recycled brass – it reduces energy consumption by 85% compared to virgin metal production.

Every small choice you make impacts our planet's future.

Market Trends and Economic Analysis

Despite recent market fluctuations, you'll find that jewelers brass remains a cornerstone of affordable luxury jewelry production.

You've probably noticed prices climbing steadily since 2023, with the cost-per-pound hovering around $4.50 – a 15% increase that's making everyone a bit nervous.

Looking ahead, you're going to see some interesting shifts in the market.

Asian manufacturers have been aggressively expanding their production capacity, which could drive prices down by late 2024.

But don't get too comfortable – there's a looming copper shortage that's keeping suppliers on edge.

If you're in the jewelry business, you'll want to keep a close eye on emerging alternatives, though nothing quite matches jewelers brass's perfect balance of cost and workability.

The market's volatility isn't going anywhere, but neither is the demand for this versatile alloy.

Design Applications and Creative Possibilities

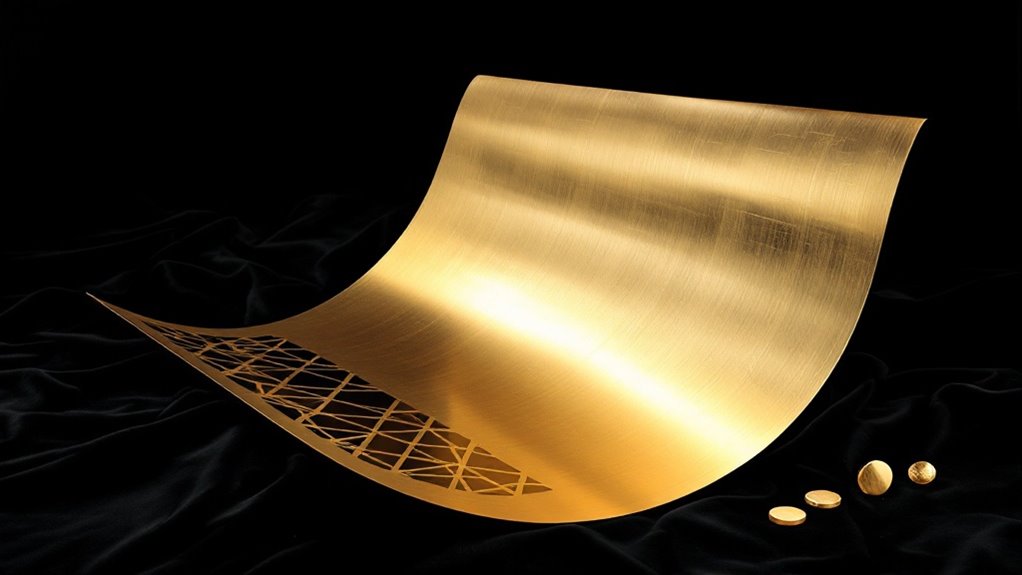

How does a single sheet of jewelers brass transform into a masterpiece that captures light like liquid sunshine?

You'll discover it's all about understanding the metal's soul – the way it yearns to be shaped, formed, and brought to life beneath your fingertips.

When you're working with jewelers brass, you're not just crafting; you're telling stories in metal.

- Picture delicate filigree work that dances like frozen lace, catching every ray of light.

- Imagine sculptural forms that seem to defy gravity, twisting upward like golden flames.

- Envision layered textures that create shadows and depth, reminiscent of ancient maps.

You've probably felt that flutter of uncertainty before making that first cut, but that's where the magic begins.

The brass responds to your touch, transforming your anxiety into flowing lines and bold statements that'll make others gasp in wonder.

Maintenance and Care Guidelines

Once your jewelers brass masterpiece captures hearts with its golden gleam, you'll need to protect that radiance from time's relentless march.

You'll notice that brass's warm luster can fade into a dull patina if you're not vigilant with its care. Don't let oxidation steal your piece's brilliance.

Keep your brass treasures in a cool, dry place, wrapped in tarnish-resistant cloth that'll shield them from humidity's creeping fingers.

When cleaning's necessary, you'll want to use a gentle brass polish – those harsh commercial cleaners will only strip away your piece's soul.

After polishing, apply a thin coat of microcrystalline wax; it's your armor against environmental assault.

Quality Control Standards and Testing

While every jewelers brass piece gleams with promise, you'll need rigorous testing to guarantee it meets exacting industry standards.

You've probably felt that knot in your stomach when submitting pieces for certification – we all have. Your reputation hangs on three critical tests:

- The X-ray fluorescence analysis that'll reveal your alloy's exact composition

- The Rockwell hardness test that'll determine if your piece can withstand daily wear

- The dreaded salt spray corrosion testing that'll expose any hidden weaknesses

Don't let test anxiety cloud your judgment.

You'll need to maintain detailed documentation of each testing phase, and trust me, those QC inspectors won't miss a single flaw.

With proper protocols in place, you can transform that nervous energy into confident precision, ensuring each piece meets ISO 9001 standards.

Comparative Analysis With Other Metals

When compared to its flashier cousins in the metals family, jewelers brass holds its own with surprising tenacity.

You'll find it's more cost-effective than gold, more durable than pure copper, and infinitely more workable than those temperamental precious metals that'll break your heart (and your budget).

While sterling silver might tarnish at the slightest hint of humidity, you can trust brass to maintain its warm, honeyed glow with minimal maintenance.

In a world where precious metals play hard to get, brass remains steadfast, glowing warmly without demanding constant attention.

What you're getting is a metal that won't make your palms sweat when you're working with expensive materials.

It's harder than copper, softer than steel, and delivers that perfect middle-ground you've been searching for.

Unlike bronze, which can be frustratingly brittle, brass flows under your tools with a predictability that'll keep your anxiety at bay.

Future Innovations and Developments

As jewelers brass evolves into the future, you'll witness groundbreaking developments that'll make your workshop experiences even more rewarding.

You're about to enter an era where smart metallurgy meets traditional craftsmanship, and believe me, it's both thrilling and terrifying.

The innovations you'll soon encounter include:

- Self-healing brass alloys that'll automatically repair micro-fractures while you work

- Nano-enhanced surfaces that resist tarnishing for up to five years

- Temperature-responsive brass that changes color under your torch, signaling precise working temperatures

You'll find yourself adapting to these quantum leaps in material science, even if they make your tried-and-true techniques feel obsolete.

The brass you've known and loved is transforming, and you'll need to embrace these changes to stay competitive in tomorrow's market.

Conclusion

You'll find that jeweler's brass continues to be a precious partner in crafting compelling creations. As sustainability shapes our selections and technology transforms traditional techniques, this marvelous metal will maintain its momentum in 2025 and beyond. Whether you're working with modern manufacturing methods or pursuing pure artisanal practices, you've got a gleaming glimpse into the golden future of this graceful, versatile material.